A number of weeks in the past, I shared a submit that takes you inside a material dye lab and teaches you all about how lab dips are made in a dye home. Now, this week, I’m going to let you know all about what goes on inside a material dye manufacturing facility after the lab dip approvals, and the order strikes to bulk.

Dye homes are one in all my favourite stops within the textile manufacturing provide chain for two causes! The primary, they’re a spectacle. Think about a whole warehouse of various machines larger than 16-wheelers. And, the second, dye homes are additionally a spot the place artwork meets science. It’s the place we create shade, however to make that shade, you want a deep understanding of chemistry.

Get able to study all about how materials get their shade in dye homes! This submit is for all my textile nerds on the market.

BUT BEFORE WE GET STARTED…

I like serving to startup model founders succeed, so I created a bunch of free guides that can allow you to with your corporation.

They received’t be free endlessly, so make sure that to seize them when you can.

WHAT YOU WILL LEARN

PREPARING FABRICS FOR THE DYE PROCESS

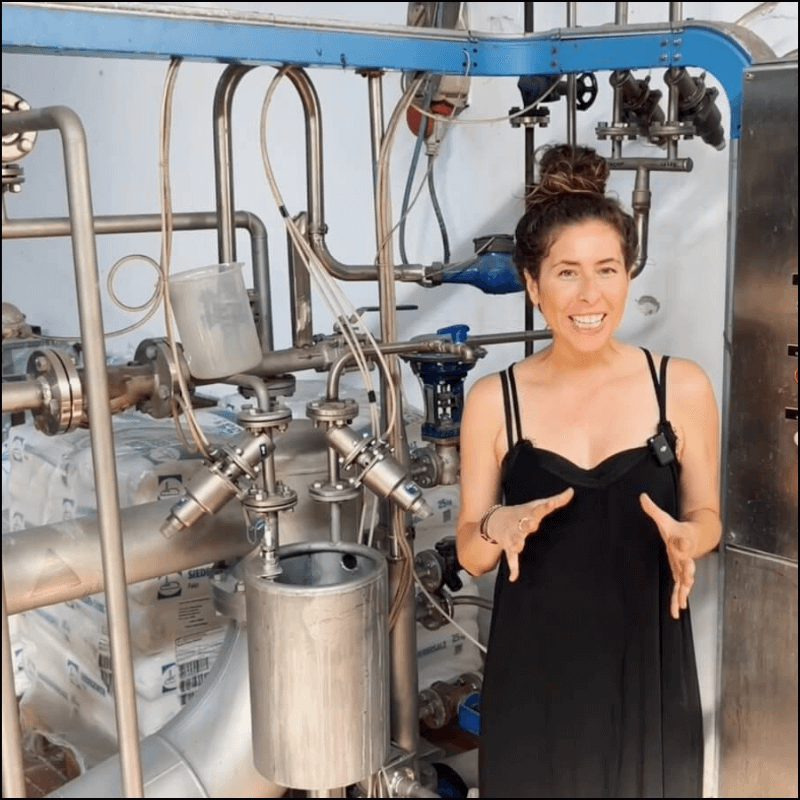

PFD material prepared for dye

There are some things that have to occur earlier than a material is able to get shade…

THE PFD PROCESS

Step one in a bulk material manufacturing order is eradicating all the colour. That is accomplished by the PFD, also called the “put together for dye” material course of. The PFD course of is a particular sort of wash that improves material dyeing. And, that is vital, as a result of when materials dye extra successfully, there are fewer model rejections, which means, much less waste. And, happier clients total.

WASH

Step one within the PFD course of includes the dye home eradicating the sizing from the material yarns. Industrial weaving and knitting machines are extraordinarily highly effective, and create materials sooner than the human eye can see. As a result of the yarns are shifting at such a quick price, they’ll turn out to be vulnerable to wreck. To forestall this, sizing coats the yarn, to assist reinforce its energy. Sizing might be product of pure elements like cornstarch, or synthetics akin to petroleum. However, whereas sizing retains a material sturdy, it additionally prevents shade from penetrating.

Consider it this manner: If you had been little, did you ever write a secret message on paper with a white crayon after which paint over it with watercolors to disclose the message? Sizing is rather like that; it repels the dye and retains the yarn white. So, the PFD course of makes use of a light-weight detergent to take away it.

WHITEN

The second step of the PFD course of includes the material dye manufacturing facility calmly bleaching the material. In its preliminary state, most, if not all, materials are barely yellow, which impacts the ultimate shade. For instance, in case you are making an attempt to dye a material a light-weight pink shade and the material is yellowish, the colour goes to come back out trying orange (since pink and yellow mix to make orange). By beginning with a pure white base, we make the method of shade matching lots simpler.

As soon as the material goes by the PFD course of, it may possibly transfer on to the massive dye machines.

HEAT TREATING STRETCH FABRICS

BTW – there’s yet one more course of f a material has stretch fibers in it, like spandex, elastane, or lycra. It wants a particular course of of warmth therapy earlier than dyeing. Not each dye home will do that additional step, however the good ones who care about high quality will.

This particular warmth therapy will assist the stretch fibers preserve their stretch and restoration by all the dye course of. That is actually vital from a high quality standpoint. If the stretch materials don’t get they warmth therapy, they have a tendency to stretch out rapidly, making a garment that can disappoint clients.

WATCH THE VIDEO

Not within the temper to learn anymore? Watch the video (no judgment).

WHAT ALL DYE MACHINES HAVE IN COMMON

Such a dye machine is particularly for cotton materials

What do all dye machines have in frequent? They contain motion and warmth.

MOVEMENT

For cloth to dye properly, it must be always shifting by the dye bathtub (water + dye). If the material and water sit, the dye (which is heavier than water) will begin to acquire in direction of the underside of the machine and create darker patches of shade on the material.

HEAT

The material must be scorching to dye properly. That’s as a result of the warmth will open up the fiber and permit the dye molecules to penetrate the fiber.

Do you know that pink colours usually have the biggest molecules, so they’re the toughest to dye? That’s the reason new pink clothes will typically flip all your laundry pink. Principally, the entire molecules that didn’t totally penetrate the fiber, are washing off.

A method to assist pink fibers persist with the material higher is to make the material tremendous scorching. The extra warmth, the extra the fiber opens up, and the extra the bigger pink dye molecules get in.

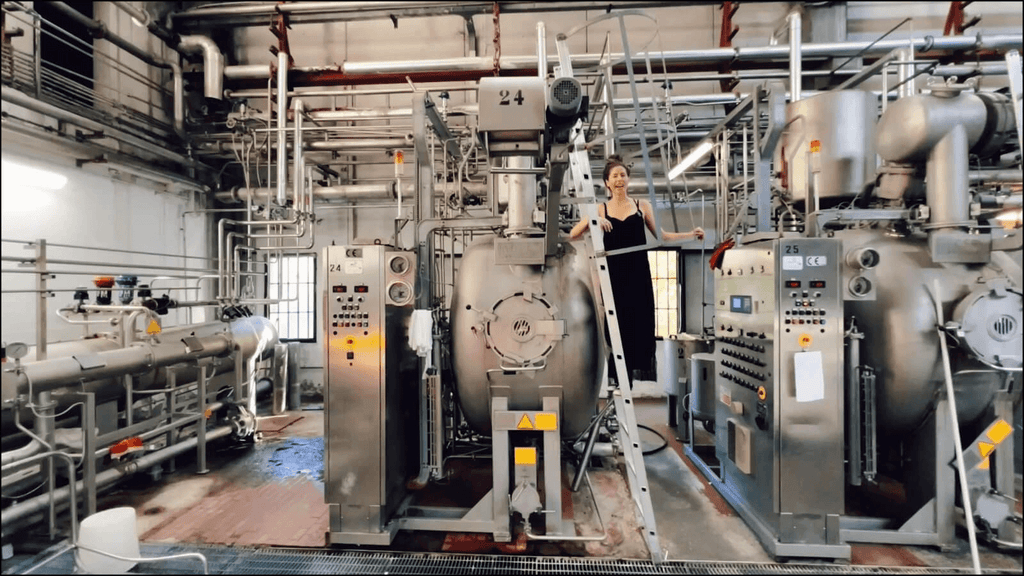

3 DIFFERENT TYPES OF DYE MACHINES IN A DYE HOUSE

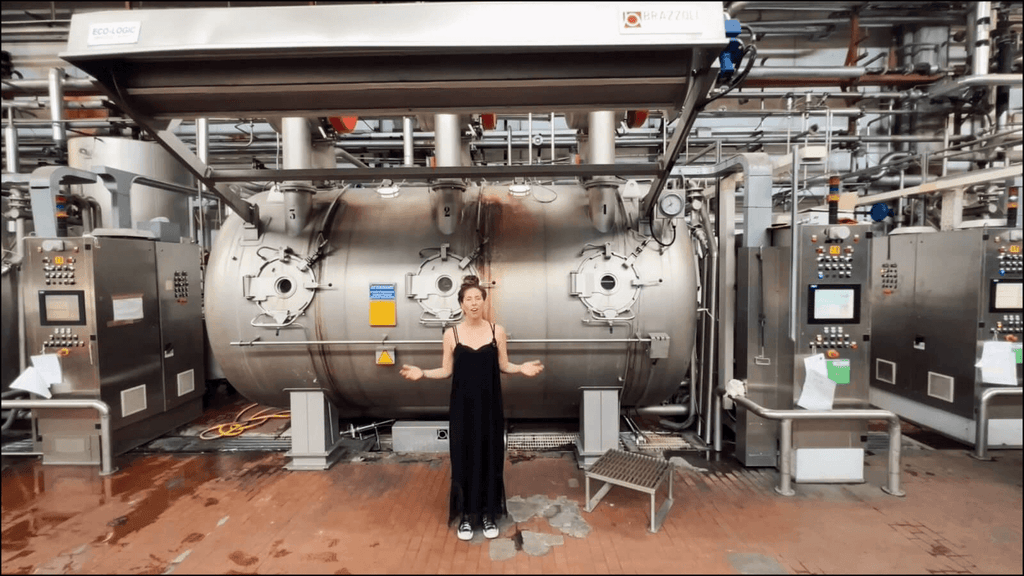

This dye machine is for all several types of materials, and might be sectioned off into 3 smaller vats to dye smaller MOQs

Now that you already know what all dye machines have in frequent, let’s speak about what makes them completely different. There are three principal forms of industrial dye machines – Polyester, Cotton, and All-Objective. Every of them operates in another way and is made for several types of fibers. Let’s break them down.

POLYESTER MACHINES

Polyester dye machines are lengthy and snake-like. The tube, roughly 20 toes in size, is totally stuffed with water and dye, and the material is snaked by the lengthy tubes for all the course of.

COTTON MACHINES

Cotton dye machines appear like big doughnuts. The manufacturing facility will fill the machines just one/2 with the dye bathtub. The material then loops round and across the circle, alternating between immersion within the dye bathtub and publicity to air. This goes on and on for typically an hour.

ALL-PURPOSE MACHINES

All-purpose machines are able to dyeing any sort of fiber. They appear like big cylinders. Usually, this kind of machine is the biggest and may dye essentially the most material, accommodating as much as 600 kilos! What’s cool about these machines is that we will part them off. The whole machine can course of a large order, or it may be break up into 3 separate compartments, every able to dealing with a extra manageable 200-kilo amount in three completely different colours. Whereas it may not be the perfect dye system for the precise fiber, this machine is beneficial for smaller orders.

LOW MOQ FABRIC DYEING HACK

This can be a pattern machine, however look how massive it’s!

Hey, my vogue startup manufacturers? Do you want a extremely small quantity of cloth customized dyed? Do this hack…

SAMPLING MACHINES

Most material dye factories may have sampling machines, that are precisely just like the bigger machines however smaller. Totally different pattern machines can run anyplace from 10 to 100 meters, or 1-2 rolls of cloth.

Usually, sampling machines are used to create a number of rolls of cloth that can permit manufacturers to make their pre-production samples earlier than they place their manufacturing orders.

However, many dye homes will let small manufacturers place pattern orders as their manufacturing order. This manner, they’ll get began with their customized materials however don’t must decide to the big minimal portions that the massive machines require.

The one draw back is that the value is considerably larger. So, if a manufacturing facility has a 1000-meter minimal, and also you, as a brand new model, solely want 100 meters, the value for the smaller order will likely be anyplace from 2-5 occasions the true manufacturing worth. That’s an enormous enhance! However, for my part, it’s nonetheless value it to have the ability to take a look at the design with a small order and get your foot within the door by constructing a relationship with an expert provide chain associate.

GARMENT DYE

There’s one final sort of machine referred to as a garment dye machine. Such a machine doesn’t dye materials, however as a substitute it’s used to dye clothes that had been already lower and sewn.

One of many advantages of garment dying is that manufacturers are capable of place larger MOQ orders in PFD, after which dye the clothes completely different colours at a later date.

A draw back to garment dying is that clothes are likely to shrink lots within the course of.

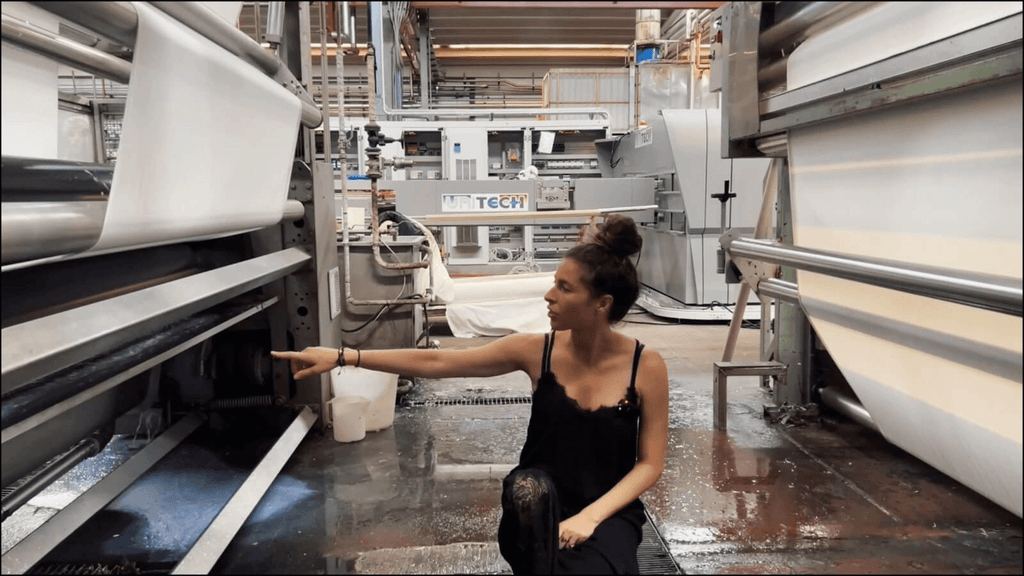

DRYING RANGE

The material is handled with a softener answer earlier than it goes by the drying a part of the machine

After the materials are dyed, they should be dried, and, right here is how that occurs:

- Moist material is fed into the dry vary.

- Then, typically, the material will get a softening therapy or a closing rinse.

- After, they clip the material onto a tenter body – a particular machine holds the width of the material in place, making certain uniform drying.

- The material is “cured” or handed by a protracted oven for drying earlier than its closing step (watch the video to see simply how lengthy it’s – it simply retains going.

-

As soon as the material is dries, one in all two issues happen:

- If the material is prepared for the client, they roll it up.

- If the material wants one other therapy, like printing, they fold it.

INSIDE THE COLOR KITCHEN

There’s dye inside all of those massive inexperienced drums

These massive machines take quite a lot of dye. And, the colour kitchen is the place it’s all saved.

In an older dye home, wheelbarrows stuffed with blended colours are carted from the colour kitchen to the machines. However, in fashionable factories like this one in Italy, the colours are drawn up by what resembles a large vacuum cleaner hose after which conveyed by a collection of tubes on to the dyeing machine.

FINISHING TECHNIQUES

That is one other pattern machine, however for poly materials

It’s also frequent for a dye home do not simply do dying providers, they often additionally do different issues like material ending therapies. These might be both chemical or mechanical. An instance of a chemical end can be a water-resistant chemical coating. And, an instance of a mechanical end is sand-washed denims, the place sand is used to put on down the material. Each are a straightforward manner so as to add textural selection and get completely different appears utilizing the identical material.

Personally, I feel each model ought to find out about these material ending hacks. Listed below are a few of my favorites:

MERCERIZATION

Mercerization is the method of immersing cotton materials in a sodium hydroxide answer. The pure form of a cotton fiber, when seen beneath a microscope after slicing a slice from it (the technical time period is cross-section), resembles a bean. However, what the sodium hydroxide answer does is trigger the fiber to swell and turn out to be spherical.

The method provides luster and energy to the material. Usually, the extra lustrous a fiber, the upper the standard (learn: luxury). And, who doesn’t need a stronger material that can last more?

To summarize, mercerization is a triple win. The method is environmentally protected, and inexpensive, and creates a textile that customers usually choose.

ENZYME-WASH

Enzyme washes are tremendous attention-grabbing as a result of they’ll do every thing, together with, in some circumstances, altering the colour of the material. Enzymes are environmentally pleasant, and, for those who ask me, are one of many keys to a extra sustainable future in material processing. I might want to create a weblog submit about enzymes sooner or later – as a result of I might speak about them for days. For now, you’ll be able to try this cool company, Novozymes, that makes a speciality of them.

MICRO-FINISHES AND OTHER MECHANICAL FINISHES

Turning French terry material into the sort of fleece you discover in hoodies, and creating that comfortable, fuzzy feeling on a flannel, are each mechanical ending processes. Primarily, the material passes by a machine with massive wire bristles, considerably resembling a canine hairbrush. These brushes gently tough up the material, leading to a fuzzy end. On a smaller scale, we will additionally use this course of to create micro-finishes, which embody materials like microsuede.

You’ll be able to watch this fast 10-second video to learn how French terry becomes fleece here.

QUALITY ASSURANCE

This material is being ready to be checked for shade variance and shrinkage

If you already know me, you are conscious (and if we’re simply assembly – take into account this) that my favourite room in any provide chain is the standard assurance room, as a result of that is the issue that may make or break a material dye manufacturing facility. The reality is, one thing is at all times bound to go wrong. Even with the most effective tools on the earth, manufacturing won’t ever be good. The great factories are those that catch these errors and repair them earlier than the product will get to a buyer.

For high quality assurance, the dye home ought to take a 20cm pattern from every roll in an order to examine for 2 issues: shade and shrinkage.

COLOR

The very first thing a dye home will do is line up the entire cuttings and create one thing referred to as a shade blanket. By putting all of the cuttings subsequent to one another, it’s simple to substantiate that the entire colours from the entire rolls match. The important thing time period to know right here is shade variance.

Now, rolls 1 and a pair of would possibly look fairly related, but when every roll has even a teeny-tiny distinction, by the point you get to roll 20, it’d fluctuate vastly. And when you have a shirt that has a sleeve from roll 1 and a physique from roll 20, it will appear like the colours don’t match in any respect. If manufacturers know the shade variance, they’ll work with their manufacturing facility strategically to make use of rolls which might be essentially the most just like each other, to make sure all parts of all clothes match.

SHRINKAGE

At this level, the material has been unrolled, stretched in all instructions, after which folded up. As a result of a lot has occurred to the material, the shrinkage could have been affected. And that could be a crucial factor for the ultimate high quality of a shirt.

Have you ever ever had a shirt, and after you washed it, it match in another way? Possibly one aspect was pulling, or the armholes felt bizarre. It’s not prefer it went within the washer and have become too small; it simply felt sort of off. Nicely, it is doable that completely different elements of the shirt shrank at various charges. To ensure a high quality product that is still good after the client washes it, the dye home ought to at all times examine each roll for shrinkage.

ENVIRONMENTAL ISSUES TO CONSIDER AT A FABRIC DYE FACTORY

Quite a lot of assets go into holding dye homes this massive operating

What did I say on the very begin of this text? Dyeing requires quite a lot of warmth and water. So, right here is how utilizing these parts impacts the setting:

WATER USE

In the present day, most factories use and reuse their water. As soon as the water is used for dyeing, it undergoes therapy to take away the dyes, making it appropriate for reuse. Now, I’m not saying that some dye homes don’t pollute and dump their soiled dye water into rivers and different locations. However, as a result of water will not be at all times plentiful in all areas, quite a lot of factories work exhausting to preserve it.

ENERGY USE

A much bigger situation in a material dye manufacturing facility is the vitality to run the machines. Nicely, I suppose that is a matter for the entire vogue business.

That can be why many provider costs are rising. When the value of oil goes up, it immediately impacts the value of textiles, and due to that, clothes as properly.

Many factories are starting the method of transitioning to greener vitality sources, akin to solar energy. However, the conversion prices are substantial, and the area required to gather sufficient vitality to function the machines exceeds what might be accommodated by only a rooftop.

TYPES OF DYE

Usually artificial dyes and chemcial dyes are used with the large machines. Natual dye materials are made in smaller batches, utilizing smaller machines.

60 SECOND RECAP

ADDITIONAL RESOURCES

WHAT DO YOU THINK?

Let me know within the feedback your favourite takeaway from this text and even your least favourite. The suggestions I obtain helps me create extra content material tailor-made to your style, so please contribute your ideas!