The primary time the manufacturing facility doorways open, it sort of feels such as you’re in an airport, besides there aren’t any indicators directing you the place to go and no gate numbers. One way or the other, everybody else is aware of precisely the place to go, and also you’re the one one misplaced. When most individuals consider a manufacturing facility, they consider stitching, however there may be SO far more happening than simply that. At this time I’ll take you on a manufacturing facility tour and clarify precisely how garments are made, from material to garment.

And right here is the perfect half. Each manufacturing facility by default, must do the identical 7 steps. I’m going to show you methods to spot if a manufacturing facility does them properly and makes a high quality product, or is reducing corners.

BUT BEFORE WE GET STARTED…

I like serving to startup model founders succeed, so I created a bunch of free guides that can show you how to with your enterprise.

They received’t be free eternally, so make certain to seize them whilst you can.

Right here’s what you’ll study on this information to how garments are made…

- A quick story about my first time in a factory seeing how clothes are made

- Going with the flow

- Fabric and materials checking

- Cutting

- Sewing

- Quality assurance

- Pressing

- Packing

- Logistics

- Additional resources

My first time in a fast-fashion manufacturing facility

Factories are thrilling, not solely as a result of it’s the place a design involves life, however due to the vitality. The primary time I walked into a quick trend manufacturing facility within the Philippines will eternally be certainly one of my trend core recollections.

Girl Gaga was blasting. Materials, bins, and other people have been whizzing previous me. And rows and rows of sewers (we’re speaking longer than a metropolis block) sat stitching as quick as they may underneath a tin roof.

The vitality was Mad Max meets night time membership meets workplace cubicles. One thing it is advisable expertise to really perceive – it’s an intensive course of.

Now, your first go to to a manufacturing facility won’t be this huge (we have been producing thousands and thousands of items of clothes on this manufacturing facility), however I promise you’ll really feel the loopy uncooked vitality of the folks behind the clothes being made in no matter manufacturing facility you find yourself in.

Anyway, let’s dive into the main points of what’s going on . . .

HOW CLOTHES ARE MADE, THE FASHION FACTORY WORKFLOW

The very first thing it is advisable perceive is {that a} manufacturing garment manufacturing facility is so much like a dwelling and respiratory organism. You possibly can consider it just like the human physique with issues always moving into, popping out, and transferring throughout. There are 1,000,000 little issues occurring that each one work collectively towards the identical purpose – making clothes.

I’ve been in a whole bunch of factories, and they’re all kind of arrange the identical method. However there may be one key distinction between smaller workshops and the massive guys which are doing high-volume orders. And that’s the entrance and exit.

Factories function like a river, which means they solely circulate a method. A lot in order that many factories even have arrows drawn on the flooring and solely enable staff (and guests) to journey in a single course.

Huge factories have the area to have a extra linear circulate with an entrance and exit on separate ends of the constructing. Materials and uncooked supplies enter on one aspect, and clothes depart on the opposite. Actually huge factories may even have two entrances (one for folks and one for deliveries of cloth, trim, tags, and many others).

However with a smaller manufacturing facility (like the type most startup trend manufacturers discover themselves in), there is just one entrance/exit. All the pieces is coming and going via one door. So the circulate is extra of a circle than a straight line. And that’s the reason issues can really feel much more hectic.

Because of this newbies usually assume bigger factories are extra skilled when that’s not at all times the case. They simply have more room and a special organizational system.

This text is generally going to concentrate on how small factories function.

STEP #1 – FABRIC AND RAW MATERIALS CHECKING

Step one in how garments are made is an inspection. (Spoiler it is also one of many final steps too).

Earlier than a manufacturing facility can begin reducing and stitching your material, they should do a material verify. Many new trend manufacturers overlook this step as a result of, actually, they don’t even know they want it. However it’s essential. Right here’s why.

Let’s faux you get your completed garment within the mail and there are stains on the material. You’ll almost definitely name your manufacturing facility in a panic, demanding to know what occurred (and asking for some a reimbursement for the damages).

9 instances out of 10, the manufacturing facility will say, “We received the material that method. Go discuss to your material provider.”

So that you’ll name your material provider and say, “Hey, what the heck occurred?”

And, you realize what they’re going to inform you? “We shipped excellent textiles. The garment manufacturing facility did the harm.”

And spherical and spherical you’ll go. By no means getting a straight reply and by no means getting compensated for the broken merchandise.

So, to keep away from all of this, material inspection is step one that can create accountability. As quickly as the material enters the manufacturing facility, it’s checked. And if there are damages, the material provider is alerted instantly, so the material will be returned or fastened earlier than it’s lower and sewn.

STEP #2 – CUTTING

As soon as the material passes inspection, it strikes onto the reducing space.

BTW, most sustainable trend startup newbies discover this step in how garments are made essentially the most attention-grabbing.

First, the manufacturing facility unrolls the material and stacks it in layers on an extended desk, often in regards to the size of a tennis court docket. They then place the paper patterns (fyi, sample making is completed in the course of the growth course of) on prime of the stacks of materials. And, lastly, they hint the patterns onto the material with both chalk or a particular pen that can disappear with water.

In spite of everything of that, it is time for reducing. However not with scissors. With a chainsaw. Yup – you learn that accurately.

It’s fairly cool to observe. You possibly can catch a glimpse of it on this video I created of the whole garment manufacturing course of for my shopper, My Little Belleville.

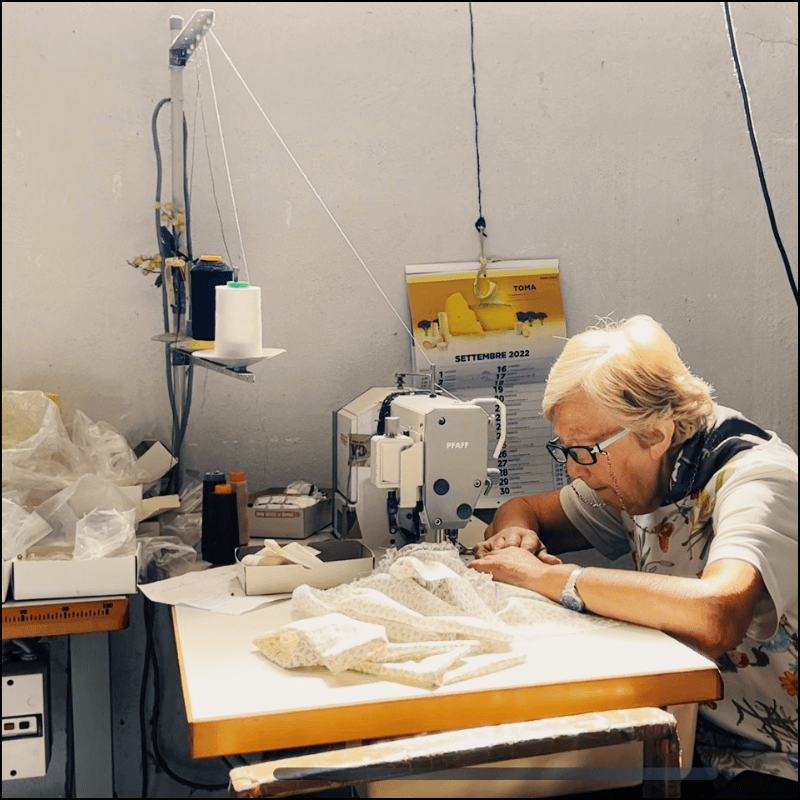

STEP #3 – SEWING

As soon as all of the sample items are lower, they’re sewn collectively. Now, simply watching somebody sew will be fairly boring (although it may very well be argued it’s crucial step, becuase it is fairly actually how garments are made).

However, right here is the place it turns into attention-grabbing.

Every member of a stitching line is chargeable for one a part of the garment. That means, one particular person sews the physique, one other the sleeves, one other the neckline, one other may placed on the labels and tags, and many others.

As you stroll down the road, you possibly can actually watch the garment come alive from a stack of lower material items to wearable clothes. It’s mainly the evolution of a garment in real-time.

STEP #4 – QUALITY CONTROL

My household works in actual property. And each time my dad considers shopping for a property, he spends about 90% of his time inspecting the basement. Whereas different patrons are inspecting the crown molding and deciding if they need carpet or hardwood flooring, we’re underground as a result of that’s the place huge costly issues are likely to go flawed.

I take an identical strategy when interviewing factories and deciding if I wish to give them my shopper’s attire manufacturing orders. I usually spend essentially the most time within the QA division. It is a actual trick of the commerce. Rookies will spend their time within the stitching room, however trend consultants comprehend it’s all about high quality assurance. IMO that is crucial step. It’s what’s going to make or break your model.

Right here’s why…

Errors occur throughout garment manufacturing.

That’s simply a part of the style course of. In case you assume working with a great manufacturing facility means all the things comes out completely, properly, that’s simply not the way it works in actual life.

In actual life, needles break and get caught within the clothes seams. In actual life, generally the colour on the sleeve of a shirt doesn’t fairly match with the physique . . . or a dimension medium will get labeled a dimension massive.

What’s vital is catching and correcting these errors.

As a result of errors are inevitable, a great manufacturing facility with a great high quality assurance program may even produce additional clothes to make sure high quality within the success of your order.

Why?

That is really certainly one of my favourite secrets and techniques to share when instructing folks about how clothes is made…

Factories know that whereas clothing manufacturing is imperfect, their shoppers count on perfection. So, they plan for about 5% in damages. That means 5 of the shirts won’t be excellent and might be tossed even earlier than they get to the client. (FYI that is excessive stage, and most of the people within the trend trade don’t even know this).

So, say you order 100 shirts from a manufacturing facility. A superb manufacturing facility with a great high quality assurance program will in all probability make about 105 shirts.

Form of wasteful, huh? That is the hypocrisy in sustainable and moral trend. Most small manufacturers don’t even know this waste is going on. They spend a lot time specializing in getting the “excellent” product, they by no means trouble to ask the way it’s attainable.

STEP #5 – PRESSING

Subsequent up is urgent. This step will completely remodel a garment. I like to consider it like a foul 90s rom-com makeover (like in She’s All That or The Princess Diaries) the place swiftly the lady is attractive as a result of she took off her glasses and straightened her hair. We will unpack that one other day. Anyway . . .

When a garment is full and comes off the stitching machine, it’s crumply, frumpy, and appears like one thing you’d discover in a discount bin within the basement of a division retailer.

The ironing and urgent are what carry it to life.

Professional tip – Not all material urgent is equal.

Plenty of factories, in an effort to save lots of time, will lay the garment flat and simply iron excessive of it. That is horrible.

The appropriate method to iron a garment is to open and press every seam individually. It takes in all probability 5 instances longer, however when a buyer tries on that garment for the primary time, they’ll really feel the distinction in high quality and match.

STEP #6 – PACKING

After propper garment urgent, it is time for packing. First in a poly bag, then right into a transport carton. This step isn’t a ton of enjoyable or very thrilling.

When the packing is completed, the model will get one thing referred to as a packing record. A packing record is what it appears like – an inventory of every carton and what sizes and styles are in every field.

That is vital as a result of generally what you order isn’t what ships. For instance, again to these 100 shirts. Possibly the manufacturing facility was solely capable of create 99 excellent shirts. In that case, you solely pay for the 99 shirts that get shipped.

It is very important at all times evaluate your preliminary PO (buy order) to your transport docs to ensure you are being charged for the proper portions.

STEP #7 – LOGISTICS + EXIT

This photograph was taken after I was working within the Philippines. Whereas the employees wait to load the cartons onto the truck, they hang around and play video games beneath within the shade. They even arrange hammocks like this one generally!

Lastly, we’ve got logistics on the exit.

That is the place garment producers stack up all of the bins with the clothes manufacturing order, and ships them out.

Now, right here is one thing to find out about transport. The key phrase it is advisable know is port metropolis. Port cities are cities the place items enter and exit. If a manufacturing facility isn’t positioned in a port metropolis, your order will must be shipped domestically to the port earlier than it may be shipped internationally.

For instance, Jaipur isn’t a port metropolis. So any clothes manufactured in Jaipur have to be shipped to Delhi first. Then it could actually ship internationally. If you wish to learn more about manufacturing in Jaipur, check out this article.

That is vital to know for 2 causes.

The primary is monitoring. A manufacturing facility may inform you your items have shipped however not present a monitoring quantity. When this occurs, manufacturers usually assume the manufacturing facility is mendacity. However what this often means is that the products first ship regionally to the port metropolis, the place they’ll have to clear customs. As soon as they clear customs, solely then will they get a world monitoring quantity.

The second purpose is timing. Having a two-step transport course of takes extra time. So that is time that must be factored into your timeline.

ADDITIONAL RESOURCES

- How to find custom clothing manufacturers for startups

- Should I hire a manufacturing consultant to source and develop my clothing line?

- A Look Behind The Seams of an Italian garment factory

WHAT DO YOU THINK?

Do you are feeling higher ready in your first manufacturing facility go to now that you simply perceive the method of getting garments made? Let me know within the feedback some other questions you might need about how factories work and the way clothes is made. Don’t be shy, it’s a fancy course of, however I’m right here to assist reply your questions.

Source link